A hybrid framework for solving multi-objective scheduling problems

Autor(en):

Abdulrahman Nahhas, Prof. Dr. Klaus Turowski

The proposed new technologies in the context of industry 4.0

challenge the current practices of scheduling in industry and their associated

research in academia. The conventional optimization techniques that are

employed for solving scheduling problems are either computationally expensive

or lack the required quality. In addition, the majority the previous works

addressed either a single objective or a weighted sum objective optimization

measure. Therefore, we propose an adaptive scheduling framework to address

hybrid flow shop scheduling problems considering multi-objective optimality

measures. The framework is motivated by a hybrid design to combine the use of

heuristic and metaheuristic approaches. The main idea behind the presented

concept is to achieve an acceptable tradeoff between the quality of the

suggested solutions for a problem and the required computational effort to

obtain them. We relied on the Non-dominated Sorting Genetic Algorithms III

(NSGA III) to design the control strategy and developed a set of allocation and

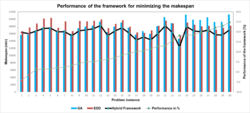

sequencing heuristics. The obtained computational results are compared to pure

metaheuristics for solving thirty problem instances that are obtained from a

manufacturing environment in the field of printed circuit board assembly production.

The preliminary computational results show that the framework fully dominates

the metaheuristic for solving 86.6 %

of the problem instances. The framework delivers a set of high-quality

solutions for solving the problem in an average of 4.5 % fraction of the required computational time of the

metaheuristic (2 minutes). Thus, it

can be employed for addressing scheduling matters in manufacturing environments

in real-time. In terms of perused objective measures, the approach delivers in

average up to 21 % better results

for minimizing four objective values than the metaheuristic as shown for

instance in Figure 1.